VOL. 1, NO. 3

The Pulse Newsletter

By TDK SensEI

Your source for updates on events, product launches, and global innovations from TDK SensEI.

Cheers to new beginnings! The Pittsburgh team came together to celebrate the grand opening of our new office—a space built for innovation, collaboration, and growth.

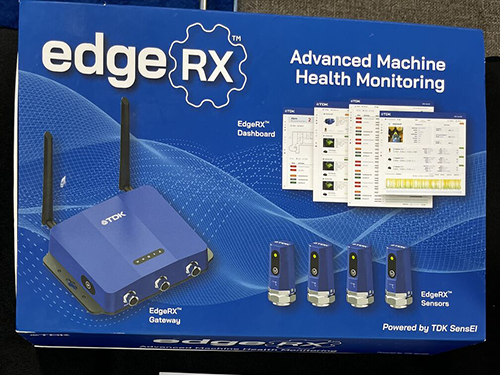

TDK SensEI at AWS re:Invent

TDK SensEI will be at AWS re:Invent—the premier cloud computing conference bringing together thousands of industry leaders, innovators, and AWS experts. We’ll be showcasing our predictive maintenance solution edgeRX along with exciting upcoming releases and announcements.

Visit us at booth #354 and Presidio’s booth (#1210) for exclusive sneak-peek demos from Dec 2–4. Plus, don’t miss our CTO, Bob Roth, delivering a lightning talk on Thursday—sharing insights on the future of edge intelligence and IoT innovation.

We’re also offering discounted tickets for attendees. Check out our AWS re:Invent info page for details—we can’t wait to see you there!

edgeRX Vision: Adding Visual Components to Sensors and AI

edgeRX Vision is TDK SensEI’s latest product designed to elevate industrial machine health through the power of machine learning and AI. By integrating Automated Optical Inspection (AOI) capabilities, edgeRX Vision enables more precise defect detection, such as anomalies, flaws, and inconsistencies in products and provides real-time insights that help improve accuracy, efficiency, and consistency in quality control processes.

edgeRX Vision is a high-speed defect detection system designed to identify small components—down to 1 mm by 0.5 mm—with exceptional precision. Driven by advanced AI, the system delivers real-time, highly accurate defect detection while significantly reducing false positives. Working in conjunction with TDK SensEI’s edgeRX sensors, edgeRX Vision enhances existing hardware infrastructure to minimize unnecessary machine stoppages and ensure a smoother, more efficient production flow. Operating at speeds of up to 2,000 parts per minute, even slight reductions in downtime can lead to substantial revenue gains—making edgeRX Vision an essential solution for high-throughput. environments.

Unlocking the Benefits of edgeRX Vision

High Velocity Defect Detection

Enables rapid identification of defects to minimize downtime and accelerate quality control on a production line

Extend edgeRX Platform to CV

Expands the edgeRX platform with computer vision capabilities for enhanced visual analysis

Precision Driven by AI

Leverages AI to deliver accurate and consistent inspection results

Real-time Visual Feedback

Provides immediate visual insights to support faster decision-making on the factory floor

Enhances AOI capability

Strengthens traditional AOI systems with intelligent automation and deeper analytics

Predictive Quality Control

Anticipates potential issues before they occur, enabling proactive quality assurance

Reduce Human Error

Minimizes manual inspection mistakes through AI automated analysis

Increase Production Output

Streamlines inspection workflows to significantly boost throughput and overall operational efficiency

Increase Product Quality

Improves defect detection and process control, resulting in higher-quality products

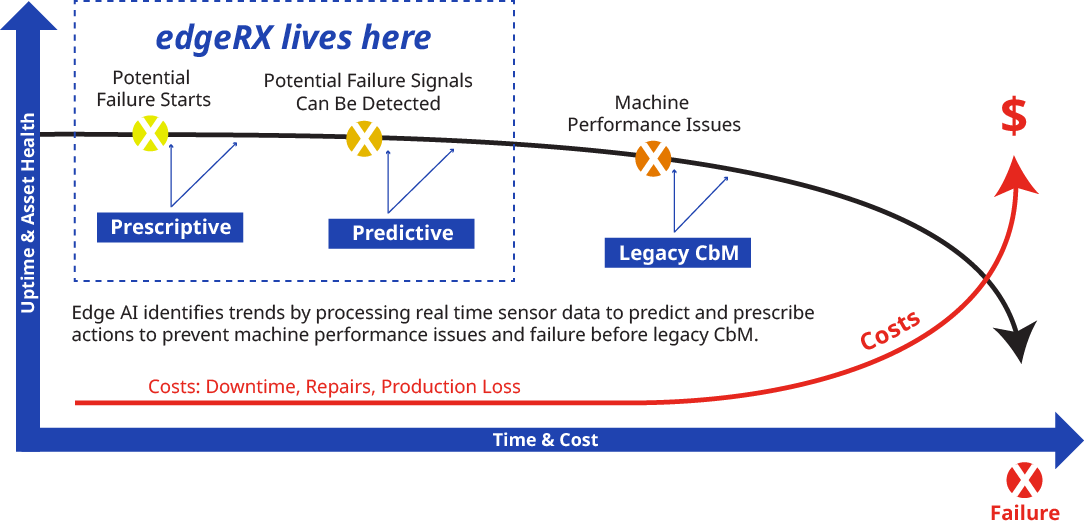

Value Proposition of edgeRX

Industrial Machine Health Monitoring

Industrial Machine Health Monitoring using AI on edge devices represents a significant leap forward in industrial maintenance. This cutting-edge approach leverages advanced AI algorithms to continuously monitor equipment health in real time using sensor data directly at the source. By integrating AI with edge computing, organizations can achieve rapid on-site data analysis and decision-making, drastically reducing machine downtime and optimizing production.

Optimize Production

Perform smarter maintenance operations through real-time data analysis directly on machines, ensuring optimal output

Maximize Uptime

Keep machines running longer through predicting and preventing downtime with AI

Smarter Visibility

Monitor critical machines from anywhere to inform decision-making and enable proactive issue resolution

Reduce Costs

Continuously monitor machine health to identify problems before they escalate to costly repairs

Roundtable Discussion: Edge AI and Predictive Maintenance

At MTS Southwest, Tim Gicewicz and Regis Santamaria shared insights on how edge AI, industrial machine health monitoring, and predictive maintenance are transforming decision-making in industrial environments. They explained how the convergence of edge computing and artificial intelligence delivers real-time insights at the source of data generation—reducing latency and boosting responsiveness. This evolution in machine health monitoring is redefining industrial reliability, operational efficiency, and long-term asset sustainability. Below are some great questions asked by our attendees!

Attendee

Is your AI solution primarily focused on sensor solutions? What are the most common industries you are seeing your solution applicable for?

Tim

Our solution isn’t limited to sensors—it can also be applied to vision systems for defect detection. In fact, many areas of manufacturing benefit from our edgeRX platform. Its applications are quite diverse, ranging from air systems in buildings to paper machines and electronic component manufacturing.

Attendee

What are the typical hardware requirements for your deployments? What do deployments typically look like?

Regis

Hardware requirements vary depending on the scale of the deployment. We’ve seen implementations that use anywhere from a dozen sensors to over a hundred. Most projects start with a smaller pilot phase, which allows us to demonstrate ROI and validate the value and cost savings before expanding to full deployment.

Attendee

What’s a digital twin as it relates to the future of AI and manufacturing?

Tim

What you can do with digital twins is essentially set up a mirror image of your factory. It allows you to simulate changes in a digital environment and see how those changes would impact your operations without disrupting actual production. This means you can test improvements, optimize processes, and predict outcomes without shutting down your physical systems.

Attendee

What are some benefits of your predictive maintenance solution?

Regis

Our predictive maintenance solution enables real-time monitoring of machine health, allowing you to address potential issues before they lead to critical failures. This could mean ordering essential spare parts ahead of time or scheduling maintenance at the most optimal moment which in turn reduces downtime and costly disruptions.

TDK SensEI Around the World

TDK Components Visit

We had great conversations with our TDK Components USA partners! We enjoyed spending time with our other TCU colleagues and walked away with some solid next steps. It is always good to connect with folks who get the tech and the business.

On the Ground in Freiburg, Germany

Vincent Broyles and Regis Santamaria had a great visit to kick off a new collaboration around smart vacuum pump monitoring — a key piece of the wafer production puzzle.

AWS Tech Summit

Senior Director of Product Engineering Jesse Legg took the stage at the AWS Tech Summit, representing our team in a joint session with AWS. It was a strong example of our growing collaboration and shared commitment to driving innovation through edge-to-cloud technology.

Marketing Team in Japan

A few members of our marketing team recently traveled to Japan to meet Toshihito Tatsumi, our newly appointed Director of Marketing for the region. The visit marked an important step in aligning global strategy with local market insights. Tatsumi-san brings deep expertise and a fresh perspective to our efforts in Japan, and the team was energized by the productive discussions and shared vision for growth.

TDK SensEI’s Newest Office in Dongguan, China

On November 3, we officially opened our new Dongguan office at the UCC Global Financial Center—marking a major milestone in TDK SensEI’s growth in China. With CEO Sandeep Pandya and China GM Zheng (Paul) Chen leading the ribbon-cutting, this new chapter strengthens our commitment to industrial innovation.

Built as a next-gen R&D hub, the Dongguan office integrates advanced sensor technology and AI to localize and scale our edgeRX line of solutions. It’s not just an expansion—it’s a strategic move to better serve China’s manufacturing sector with smarter, faster, and more localized solutions.

We’re excited to deepen partnerships, respond swiftly to market needs, and help drive high-quality development across industries.

Recent Events

Smart Water Summit

The Smart Water Summit was a refreshing change of pace—pun intended! This intimate event gave us the chance to catch up with industry leaders tackling water infrastructure with data and innovation. The takeaway? Intelligence belongs in every drop.

Turbomachinery & Pump Symposium

We participated in TPS to engage with professionals advancing turbomachinery and pump technologies. The symposium offered in-depth technical sessions and valuable discussions on equipment reliability, system performance, and engineering innovation. It was a productive setting for knowledge exchange and industry collaboration.

Water Environment Federation’s Technical Exhibitions and Conference (WEFTEC)

WEFTEC provided a comprehensive overview of current developments in water infrastructure, treatment, and sustainability. Our team appreciated the opportunity to connect with experts and organizations committed to improving water quality and operational efficiency. The event reinforced the importance of data-driven solutions in environmental management.

Society of Maintenance and Reliability Professionals (SMRP)

At SMRP, we joined a focused community dedicated to advancing maintenance and reliability practices. The conference facilitated meaningful dialogue around asset management, predictive maintenance, and workforce development. It was an excellent forum for sharing expertise and strengthening professional networks.

Manufacturing Technology Series Southwest

At MTS Southwest, Regis and Tim led a short session on how Edge AI is transforming industrial machine health monitoring. They discussed the shift from traditional condition-based methods to real-time, predictive strategies powered by AI at the edge. The session highlighted how these technologies are improving responsiveness, reducing downtime, and enhancing operational efficiency.

Combined Exhibition of Advanced Technologies CEATEC

TDK SensEI proudly showcased edgeRX at CEATEC, Japan’s premier technology exhibition. Together, we’re shaping the future and driving the evolution toward Industry 5.0!

Japan IT Week

Japan IT Week, DX Week, Sales & Digital Marketing Week, and EC & Store Week unite the latest innovations in IT, digital transformation, marketing, and e-commerce. Each event offers unique opportunities to explore emerging trends, connect with industry leaders, and solve business challenges. This year, we proudly showcased edgeRX at select partner booths, demonstrating how we’re driving smarter, more efficient solutions for the future.

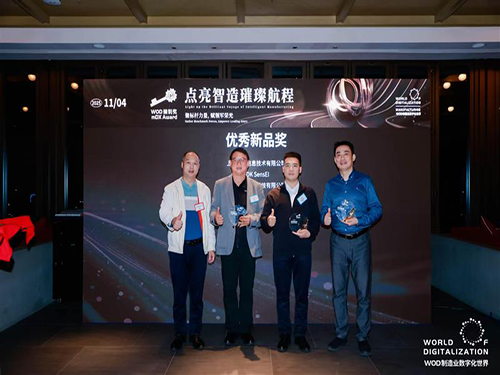

Shenzhen Manufacturing Digitalization Expo

TDK SensEI participated in the Shenzhen Manufacturing Digitalization Expo at the Shenzhen International Exhibition Center (Bao’an), held in conjunction with the DMP Greater Bay Area Industrial Expo. Our focus was on tackling equipment operation and maintenance challenges while showcasing the concept of “Smart Sensing + Edge AI” for intelligent management.

Leveraging the technological innovation and industrial value of edgeRX, TDK SensEI stood out at the expo, earning two prestigious honors: the “Digital Enterprise – Excellent New Product Award” and the “Application Scenario – Digital Agility Award.” During the event, TDK SensEI APAC Sales Director Jie (Jeff) Bing delivered a keynote titled “From Reactive Maintenance to Proactive Prediction: edgeRX Empowers Intelligent Equipment O&M.” His presentation highlighted the core benefits of predictive maintenance and its transformative impact on the industrial sector.

Upcoming Events

December 8-11

International Maintenance Conference – Florida

Visit us at Table #6 to explore edgeRX, our advanced Edge AI solution for predictive maintenance. Discover how edgeRX delivers real-time insights, reduces downtime, and optimizes asset performance.

Join us to experience the future of reliability engineering and accelerate your journey to smarter maintenance!

December 9-11

Energy Live – Houston

Join us in Houston, December 9–10, for this premier energy event. Visit booth 503 to experience our new edgeRX demo—test your skills against AI and see how edgeRX delivers real-time analytics and intelligent sensors to cut downtime, boost performance, and drive digital transformation.

Discover how TDK SensEI is redefining maintenance for the energy sector!

December 10-12

Japan Build Tokyo

TDK SensEI will be at Japan Build Tokyo, a leading technology exhibition for architecture, civil Engineering, and real estate-This exhibition is Japan’s largest specialized trade show, bringing together the latest products that solve specific challenges in these industries. Come visit us to see how we can help in smart building, manufacturing, and predictive maintenance!

December 10-12

MONOist DX & AI Forum 2025

We’re excited to join the MONOist DX & AI Forum, an online seminar taking place December 10–12, 2025. This event explores the future of manufacturing digital transformation and the potential of AI, bringing together over 500 professionals driving innovation in factory operations, IT planning, and business process improvement.

TDK SensEI will share insights on how Edge AI and smart sensing can accelerate DX adoption and unlock new efficiencies in manufacturing. Stay tuned for highlights from this important industry event!

December 19

Manufacturing DX & AI Forum Tokyo 2025 Winter

We’ll be joining industry leaders at the Manufacturing DX & AI Forum on Friday, December 19, 2025 in Tokyo. This event explores the future of Japanese manufacturing through Physical AI, Edge AI, and Digital Twins, showcasing how AI and human collaboration can drive innovation.

As Japan faces critical challenges—from demographic shifts to global competition—digital transformation and AI adoption are key to building resilient supply chains and next-generation smart factories. The forum will feature cutting-edge technologies, case studies, and strategies shaping the future of manufacturing.

Stay tuned as TDK SensEI shares insights and solutions that empower the next era of industrial innovation!

A Word From Our Chief Product Officer

“Innovation isn’t about replacing humans with machines—it’s about amplifying human potential through intelligence.”

Sundeep Ahluwalia

CPO, TDK SensEI