i3 Micro CbM Sensor

The world’s first edge AI-equipped wireless mesh network compatible sensor module

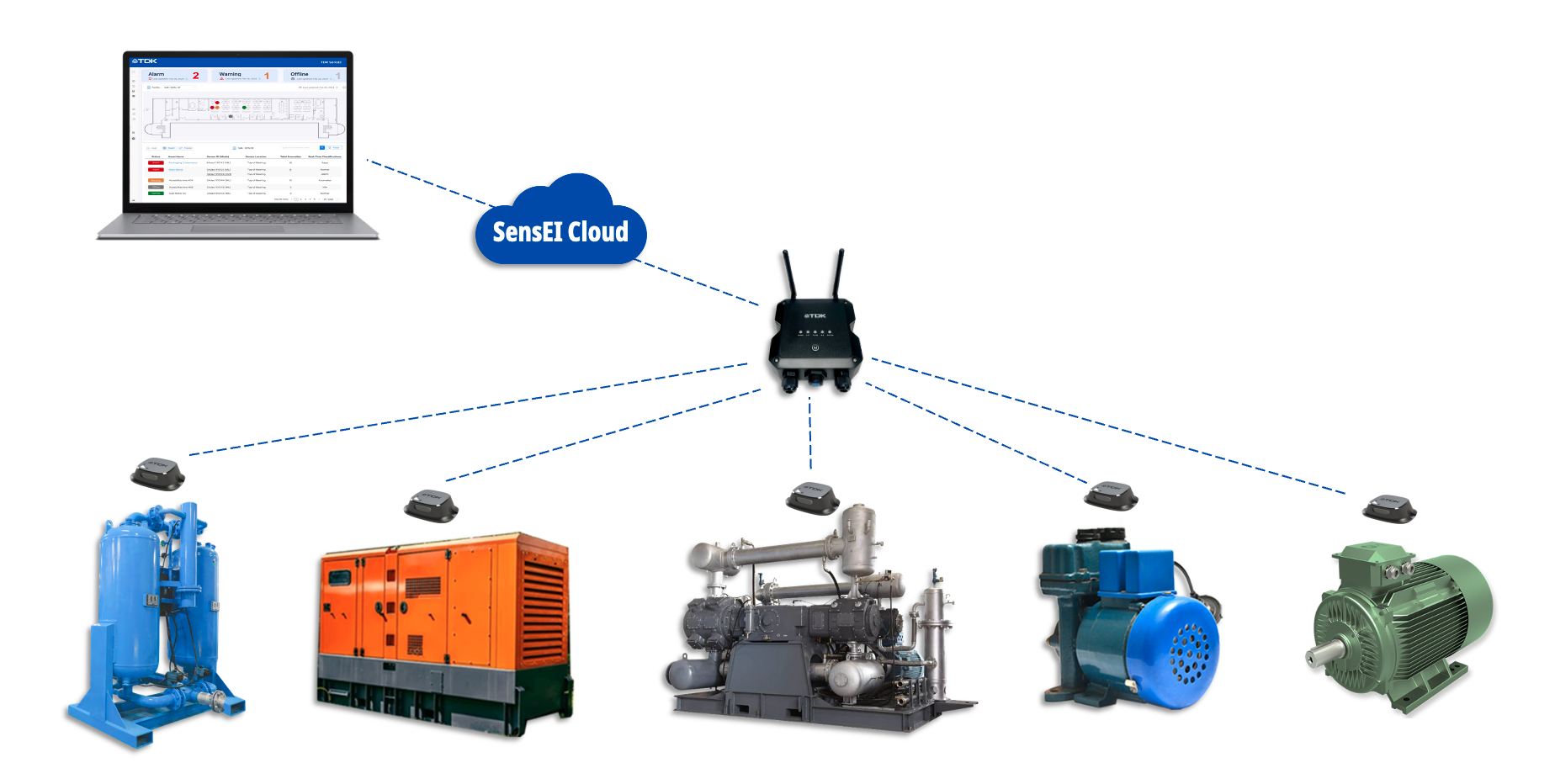

The i3 Micro CbM Sensor module was designed to revolutionize predictive maintenance in manufacturing. This all-in-one solution includes a sensor module, network controller, and software, enabling seamless data collection, processing, and condition monitoring to reduce unexpected downtime and boost productivity. With battery-powered operation, edge AI capabilities, and wireless connectivity that supports up to 100 sensor modules, this system provides unparalleled installation flexibility, making it easier than ever to implement advanced monitoring across manufacturing sites.

Key Features and Benefits

- Edge AI: Determine the status of machines and equipment in real time. No external network is required, reducing the risk of information leaks.

- Wireless mesh network: Simply install the i3 Micro Modules and they will automatically form a network.

- Small sensor module: Small in size and dustproof/waterproof IP54 compliant. Sensing can be done in the most suitable location.

- Battery-powered: Easy to install without the hassle of wiring.

Specifications

| Communication method | USB / Bluetooth ® *1 low energy / Wireless mesh |

| Power Specifications | USB power supply / coin type lithium battery |

| Storage and use temperature range. | -10 to 60°C (-10 to 60°C) |

| Appearance | 55.8 × 40.5 × 20.0 mm |

| Protection rating | IP54 |

| weight | 30 g (excluding batteries) |

| 3-axis acceleration sensor | Detection range: ±2, 4, 8, 16g Data rate: 1, 2, 4, 8kHz |

| Temperature Sensor | Detection range: -10 to 60°C |

At production sites such as factories, it is required that machines and equipment operate at 100% capacity, but productivity can decline due to unexpected downtime or a shortage of on-site engineers. For this reason, there is a demand for real-time monitoring of the status of machines and equipment using sensors, without relying on human labor. However, there are two major challenges to achieving this real-time monitoring. The first is that the process from collecting and processing the acquired data is complex, making it difficult to utilize the analysis results. The second is that in many cases, sensing cannot be performed where the user wants due to wiring and physical constraints, making optimal status monitoring difficult.

The i3 CbM Solution simplifies the complex process from data acquisition to machine and equipment monitoring, allowing anyone to quickly introduce data-based predictive maintenance to the field. The vibration data is acquired by a module installed on the machine or equipment, and the edge AI operating within the module determines the change in condition. This allows signs of failure to be detected in real time without relying on human intervention. In addition, the i3 Micro Module is small, has wireless communication capabilities, and can be battery-powered, so it can be installed in the optimal location without the need for wiring. In addition, it automatically forms a wireless mesh network, allowing multiple i3 Micro Modules to be operated, and the network is automatically re-formed when additional modules are added.